Introduction:

Non-woven fabric is rapidly replacing traditional plastics and becoming highly preferred due to its cheap manufacturing cost and being environment friendly. Different types of Non-woven fabric manufacturers are working overtime to keep up with the demand and suppliers are on the lookout for quality non-woven fabric factory to provide their clients with the best non-woven fabric they can.

What is Non-Woven Fabric?

Basically, non-woven fabric is a type of fabric that is made with no interwoven strands that are indigenous to traditional woven fabric used on a daily basis. The fabric does have an organized internal structure but it is primarily made by placing fibers together and then using one of the many available methods to combine those fibers into a unified material that is identical to the traditional fabric that we use. Non-woven fabric requires neither knitting nor weaving; instead, it gets treated either mechanically, chemically, or with heat to make the fibers stick together in a cohesive fabric.

Types of Non-Woven Fabric:

There are many different types of non-woven fabric classified on the basis of how the fabric is manufactured. The primary types that are popular for everyday applications include:

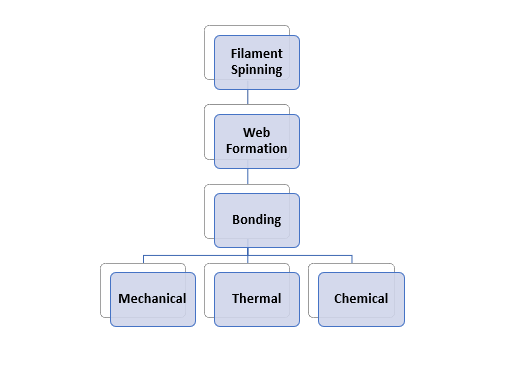

1. Spun-Bounded Non-Woven Fabric:

Spun-bounded non-woven fabric utilizes polymers as the raw material for its formation. The process involves the polymers to go through extruder so it can get stretched to form a continuous filament which is laid into a web, followed by melting and spinning so that the randomly laid web can get inter-tangled. Finally, the fabric is formed when the web is treated either chemically, by application of heat to make the polymer melt and stick, or mechanically where pressure makes the polymer stick strongly.

2. Spunlace Non-Woven Fabric:

Spunlace non-woven fabric got its name from the process. The process utilizes applying high-pressure water jet to the layers of the web fibers so they can get entangled and combine into a uniform fabric. The fiber used for this process includes nylon, polyester, silk, bamboo fiber, viscose fiber, wood pulp and many others. The process reinforces the webs to some degree but they are still not as strong as many other types of non-woven fabric. Spunlace non-woven fabric is quite popular for its application in the manufacturing of face masks, disposable surgical gowns, wet wipes, filter, etc.

3. Heat Bounded Non-Woven Fabric:

Heat is the main agent used in this type of non-woven fabric to bind the fiber webs together. Adhesives are added to the layers of fibrous webs which are then treated with heat that melts the adhesive and then cooled which combines the multiple layers into a single fabric-like material.

4. Airlaid Pulp Non-Woven Fabric:

Also called dustless paper, air-laid paper, and dry paper non-woven; it uses air-laid technology which opens up the wood pulp fiberboards into a state of a single fiber. Then it uses a strong flow of air to combine the wooden fiber on the web and finally reinforces the pulp on the web to form the non-woven fabric.

5. Melt-blown Non-Woven Fabric:

Melt-blown non-woven fabric is made in a complex systematic procedure where melted polymer fiber is extruded through a linear die. The die contains hundreds of tiny holes that turn the melted polymer into thin fibers. The fibers are cooled by blowing hot air, and the resulting web is collected on a collector screen where they combine to form the non-woven fabric that is fined, filtered, and self-bonded. Melt-blown non-woven fabric is usually added to spunbond non-woven fabric to make webs for SM and SMS fabrics.

6. Wet Non-Woven Fabric:

Wet non-woven fabric is manufacture in a number of steps. First, the raw material comprising of fibers is placed in an aqueous medium to open into a single fiber. Next, different fibrous raw materials are added to form fibrous suspension slurry. The slurry is then treated in a mesh forming mechanism and the mesh is then laid in the wet state it is treated in to form the fabric.

7. Stitch-Bonded Non-Woven Fabric:

Stitch-bonded non-woven fabric is another type of dry non-woven fabric that uses a loop structure that is wrap-knitted so it provides strength and structure to the layers including yarn layer, fiber web, and other materials used during its manufacturing. The combination of different layers reinforces the structure of the fabric.

8. Needle-Punched or Acupunctured Non-Woven Fabric:

Needle-punched non-woven fabric or acupunctured non-woven fabric is another dry-type fabric which is made by reinforcing fiber into cloth by using needle punching. It has a rough texture and the fabric produced this way is quite strong.

9. Hydrophilic Non-Woven Fabric:

One of the most popular types of non-woven fabric, it is primarily used for manufacturing medical materials such as napkins (for sanitary purposes), sanitary pads, etc. because it is soft to touch to doesn’t scratch the skin.

Properties of Non-Woven Fabric

Non-Woven fabric is used these days for a vast number of applications. It is preferred primarily because of its affordability when it comes to production; also, it is environment friendly which makes it an excellent alternative to plastic and other materials which are not biodegradable. But since the fabric is light in nature and weaker than fabric made by knitting or weaved. Non-Woven fabric is not suitable for clothing or applications that require durability, but it is ideal for applications which require disposing of used material such as in the field of medical science.

Some of the most popular applications of the non-woven fabric include:

- It is used for making disposable gowns that are used in hospitals.

- It is also used for making disposable protective wear.

- It is popular for making medical face masks and surgical face masks.

- Currently, it is in high demand for making Coronavirus safety products.

Due to an increase in the demand for Coronavirus safety wear, many suppliers are manufacturing sub-par quality non-woven fabric. So, when opting for ordering non-woven fabric, be sure to only go for experienced and top-grade non-woven fabric suppliers. The best course to take is choosing a non-woven fabric manufacturer who has been in this business since before the pandemic