Introduction

Non-Woven fabric has taken the market by storm and it won’t be entirely wrong to say that non-woven fabric manufacture is somewhat a lucrative position for people in related industries. Primarily due to the increased demand for this fabric which has even made it hard for non-woven fabric suppliers to keep up with the demand. But this also calls for caution as new entrants are trying to take advantage of this situation by manufacturing sub-par quality non-woven fabric which is available at an even cheaper rate.

Therefore, it is advised to only opt for non-woven fabric suppliers that have been operating in this industry for several years. Since the non-woven fabric is available in a number of types, it becomes quite difficult to determine the right type of fabric that must be used for a particular application. One of the most popular types of non-woven fabric is the spunbond non-woven fabric.

Spun-Bond Non-Woven Fabric:

The spun-bond non-woven fabric got its name from the process itself. As the general process of forming non-woven fabric involves boding or interlocking the fibers used in the process of manufacturing either:

- Chemically (this also involves using solvents).

- Mechanically

- With the application of heat.

The initially manufactured web structures that are made with treated fibers undergo one of the above state methods to form the non-woven fabric. Different non-woven fabrics have different structures, different degree of integrity, hence different applications. This is why it is essential to be aware of the fabric type and its properties.

Coming back to sup-bond non-woven fabric; it is manufactured in a systematic way which includes the following steps:

- The technique used for making spun-bond non-woven fabric involves a technique called melt spinning.

- The spun-bond non-woven fabric is usually made by spinning continuous filament fibers on a moving belt.

- The raw materials used for this process includes fibers made from polyethylene, polypropylene, polyester, etc.

- The raw materials are first dried, then melted with heat, then sent to an extruder.

- The extruder is laced with hundreds of tiny holes that form filaments from the melted raw material to form web structure.

- The fibers/filaments are then cooled with hot air and laid on a moving conveyer belt where they intermingle to form a web structure.

- The continuously emerging numerous filaments are made thin by stretching and solidified with warm air. This process ensures that the fibers have a structure before they are laid on the belt.

- The entangled filaments are that get laid on the moving belt are subjected to a bonding chamber where they are treated either chemically, mechanically, or thermally to form a solidified fabric-like structure.

Though the process varies and due to the latest advancements in the industry, there are various options and new procedures to form a better and high-quality spunbond non-woven fabric. But the basic procedure is similar to the one stated above and all the latest advancements are different variations of the base process.

Main Types of Spun-Bond Non-Woven Fabric:

Although spun-bond non-woven fabric itself is a type of non-woven fabric; it has many sub-types which are made from a combination of different types of non-woven fabrics. The three main and most popular types of spun-bond non-woven fabric include:

1. S-Type Spun-Bond Non-Woven Fabric:

S-Type Spun-Bond Non-Woven Fabric is the original or the base type of Spun-Bond Non-Woven Fabric. It is a single-layered Spunbond Non-Woven Fabric and other variations have to do with different materials being involved or addition of an entire layer of a different type of non-woven fabric.

2. SS-Type Spun-Bond Non-Woven Fabric:

SS-Type Spun-Bond Non-Woven Fabric is the second main type of Spunbond Non-Woven Fabric. It is composed of two layers of the Spunbond Non-Woven Fabric; which basically means S-Type Spunbond Non-Woven Fabric + S-Type Spun-Bond Non-Woven Fabric.

3. SSS-Type Spun-Bond Non-Woven Fabric:

Just as the name suggests, it is the third main type of Spun-Bond Non-Woven Fabric which is basically S-Type Spunbond Non-Woven Fabric + S-Type Spun-Bond Non-Woven Fabric + S-Type Spunbond Non-Woven Fabric; which in turn forms SSS-type spun-bond non-woven fabric.

Characteristics

Spun-bond non-woven fabric has the following general properties:

- Due to its process of manufacturing, its fibrous structure has a random layout.

- The fabric has high opacity which is reduced as we move from S to SSS-type spun-bond non-woven fabric.

- In comparison to other non-woven types, spun-bond has a high strength to weight ratio.

- The tear strength on spun-bond fabric is quite high.

- Thanks to the random layout of the fibers involved in the making of spun-bond fabric, it has planar isotropic properties.

- The crease and fray resistance of the spun-bond non-woven fabric is significantly high.

- Due to high void content, spunbond non-woven fabrics have a high liquid retention capacity.

- In-plane sheer resistance is high with low drape ability.

- Spun-bond non-woven fabric has high breathability, along with good resistance against fluid penetration.

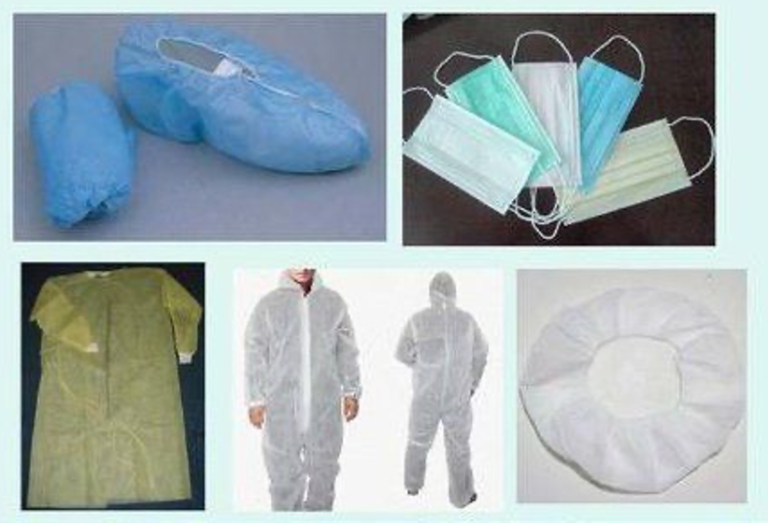

- Two main qualities of spunbond non-woven fabric which make it suitable for medical applications are sterilizability and resistance against bacterial penetration. This is why it is highly preferred for making disposable hospital gowns, gloves, shoe covers, and even antibacterial coverings for medicine and other sensitive supplies.

Overall, the applications of spun-bond non-woven fabric are quite versatile. The uses are expanding and new developments are being made to make the fabric more durable and to increase its applications. Even now, the applications of spunbond non-woven fabric surpass many other types of non-woven fabrics. The easy and popular process of manufacturing makes spun-bond non-woven fabric one of the most popular types available in the market.

Non-woven fabric manufacturers are using spun-bond non-woven fabric to manufacture hospital patient gowns and other protective wear. Currently, a high number of Coronavirus safety supplies are being manufactured from spun-bond non-woven fabric including medical face masks, surgical face masks, disposable isolation gowns, Coronavirus safety masks, and a variety of other Coronavirus safety wear. S, SS, and SSS type spun-bond non-woven fabric have their own applications and in their own way, they are quite beneficial.