Melt Blown Polypropylene?

You are interested in textile, and you do not know much about what Melt Blown Polypropylene is! You can not appreciate it. So this article is for you if you want to be involved in the textile industry. You can understand Melt Blown Polypropylene properly after glancing at this article to the end.

What is Melt Blown Polypropylene?

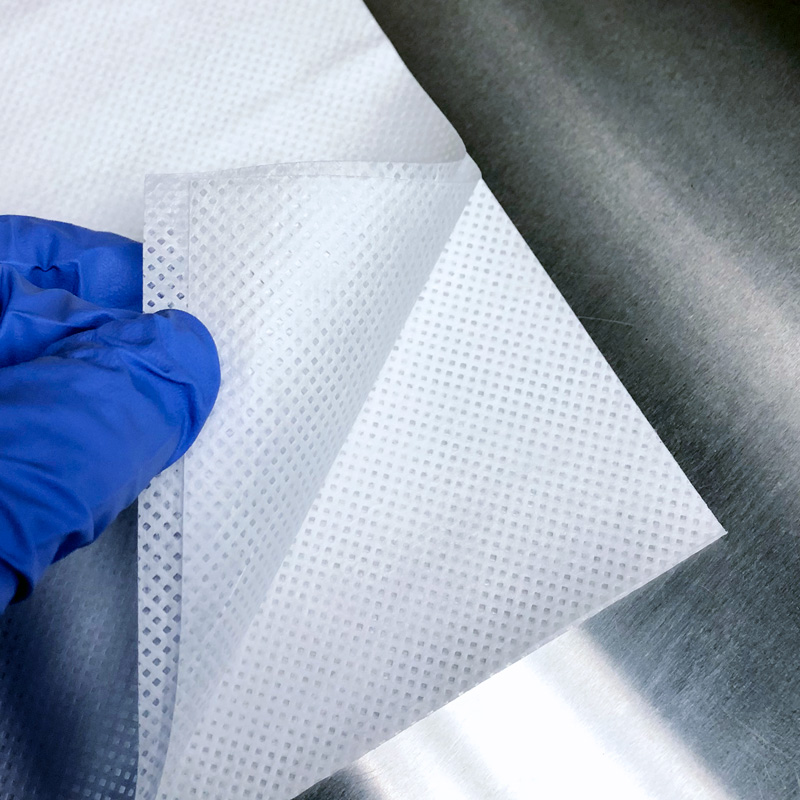

- For knowing the details of melt-blown polypropylene, you have to know about melt-blown first. Melt blown is a manufacturing process of non-woven fabric. You can convert a polymer into a continuous fiber by using this process. In 1945 this melt-blown procedure started its journey, and in 2021 it became a popular method in a textile that improved the industry at a high level. Now polypropylene! The short form of polypropylene is PP. Polypropylene is a thermoplastic that is made from propylene monomers. The melting point of PP is 160 degrees Celsius, and its approximate density is 0.855 g/cm^3. It is a necessary element in textile commerce.

- Currently, you can get a clear view of What melt-blown polypropylene is. Polypropylene is a common polymer for producing non-woven fabric. Melt-blown is the manufacturing method.

Procedure

Melt blown polypropylene process is a conventional fabrication and one-step process. Here high-velocity air blows a molten thermoplastic called polypropylene polish from an extruder die. Then direct into a conveyor; otherwise, take up the web for forming an excellent fibrous web that is self-bonding.

Properties of Melt Blown Polypropylene

A. Give a high surface

B. Increased porosity

C. Great softness makes the fabric quality great

D. Last but not least, super absorbance power due to their microstructure.

Steps of making PP Melt Blown Polypropylene non-woven from melt Blown Polypropylene

Step 1

Polymer feeding is the first step. You have to use the propylene monomer for making the melt-blown polypropylene non-woven fabric.

Step 2

The second step is melt-blown extrusion. We already explained the procedure above.

Step 3

Now comes the fiber formation phase, and you get your fiber.

Step 4

Fiber cooling arrives after fiber formation, and you need to chill the fiber for an adequate period.

Step 5

Net formatting where you have to format net from your fiber.

Step 6

It is the last step, and it is strengthened for shaping in cloth.

Uses of Melt Blown Polypropylene

You can use melt-blown polypropylene to make melt-Blown polypropylene non-woven fabric. It has several uses in different sectors.

1. Melt-blown polypropylene non-woven fabric used for making air filtration equipment.

2. As polypropylene is a thermoplastic, it helps to generate thermal filtering substances.

3. In this pandemic time, the mask has become a basic demand. Melt-blown polypropylene non-woven fabric assists in producing the materials of the mask. The most protective N95 and PPE kits are also made from PP melt-blown non-woven fabric.

4. Melt-blown polypropylene is a vital fabric for absorbing material, liquid filtering materials.

Application areas

- Agriculture stuff

The agriculture field needs many cloth stuff for protecting crops, irrigation cloth. The PP melt-blown non-woven fabric is needed for making all of this agricultural stuff.

- Health care field

PP melt-blown non-woven fabric is widely used in the medical area. PPE kits, surgical masks, body coveralls, surgical gowns, diapers, etc., are made from this useful fabric.

- Home Decor

Bedsheets, wall cloths, table cloths are all generated from PP melt-blown non-woven fabric.

- Garments industry

Melt-Blown polypropylene is very necessary for leather-based clothing, adhesive lining, even for shaped cotton.

- Environmental impacts

Melt-Blown Polypropylene is not toxic, has no toxic emissions like fluorocarbons and halogens. So they are not harmful to the environment. But it is not biodegradable. You need to recycle the Melt-Blown Polypropylene products. Otherwise, it will cause soil and water pollution.

Final Verdict

Melt-Blown Polypropylene is an influential component of the textile industry. Its application area is very large. But this is not biodegradable, so have to