Cotton fabrics are widely used in our daily lives because of their unique softness, breathability, warmth retention, comfort and biodegradability. Natural and inexpensive requirements have created a demand for suitable materials that can entirely repel oil and water. To exhibit superhydrophobic properties, the wettability of the material is required for specific oil and water repellency mapping. Cotton is usually used to obtain oil and water repellency, so its quality is moderate And lightweight. However, they are unlikely to remain stable in corrosive chemical environments. Many efforts have been made to wipe with hydrophobic cotton, but commercially available hydrophobic cotton or sponges are still rare. However, here in this article, we will discuss hydrophobic non woven fabric and its properties.

Basic information

The degradation of the matrix material and the instability associated with the fungal environment or mechanical friction limit practical applications. As the model of Wenzel and Cassie-Baxter shows, the corresponding multi-scale hardness can make the ideal hydrophobic surface more and more hydrophobic because the air under the beach ball is trapped like a cushion.

Many reports prove the potential of making hydrophobic materials by mixing low surface pot life and suitable challenging geology, as well as the oil and water repellency potential of using such materials. Due to the importance of this field, researchers are constantly striving to find effective methods or materials to repel oil and water.

Properties

Nonwoven cotton is characterised by unparalleled suction and discharge performance, high wearing comfort and abrasion resistance. The cotton texture imparts different properties such as bulkiness, water resistance, versatility, elasticity, and softness. It also has fire protection, washable, packaging, heat insulation, sound insulation, filtration, use as a bacterial barrier and sterility benefits].

The traditional strategy is characterised by low productivity, low selectivity, serious waste, and poor recyclability. Some fundamental limitations of conventional technologies, exploration of new materials, and more complex strategies continue. Here, we have discussed some properties of hydrophobic non woven fabric with scientific explanation and tests. You will able to understand the properties with scientific methods and tests. Let’s discuss them.

The influence of temperature

As the fabric is hydrophobic, the temperature has a significant influence on it. It has been observed that when all parameters are the same, however, due to temperature changes, the results indicate a greater likelihood of contact. To test the effect of temperature, if you took 2 ml HDTMS and 40 ml ethanol and changed the temperature to 40°C, 50°C, 60°C, and 70°C. By measuring the contact angle at different temperatures. As the temperature increases, the contact angle also increases to 60°C, because as the temperature increases, more αOH groups are exposed to the solution, and HDTMS is more substantial, and cotton polar fleece is networked.

After that, the contact angle decreases. Therefore, the optimal temperature is chosen to be 60°C. But, there is a reason why the contact angle decreases after reaching 60°C. The boiling point of ethanol is 78.24°C. As a result, the increase in temperature makes it difficult to open more -OH groups in the solution. Another issue is that higher temperatures will cause the characteristics of the cotton worse. Therefore, the maximum contact angle observed at 60°C is 123.7°.

Stirring time

As long as it is hydrophobic, the stirring time has a significant influence on cotton. It is found that if all the parameters are the same, but due to the change of mixing time, the result shows that the contact angle changes. When checking the effect of stirring time, we took 2 ml HDTMS and 40 ml. ethanol at a temperature of 60°C and changed the stirring time to 2 h, three h, four h, five h and ten h. The influence of different temperatures by measuring the contact angle of other stirring times.

The maximum contact angle observed after 3 hours was 127.4°. As the time interval increases, the contact angle decreases relatively. So, if the time in the shaking bath is longer, the lint will stay under reflux for a longer time. After a certain period, the fluff will decompose to form the smallest contact angle. In principle, the contact angle drops after 4 hours.

The effect of different amounts of ethanol

On the same materials and parameters, the amount of ethanol is almost unaffected. In the first experiment, after using 3 ml HDTMS and 50 ml ethanol at 60°C for 10 hours with a stirring speed of 10, it was measured that the contact angle of the sample. But in the next experiment, it was tested the amount of ethanol to understand how the amount of ethanol affects the non-woven fabric. Later we used 40 ml, 60 ml, 70 ml and got different contact angles. The observed contact angles are almost the same.

Water contact angle measurement over time

For this measurement, an optimised sample with a contact angle of 127.4° was obtained and prepared using 2 ml HDTMS, 40 ml ethanol, and a temperature of 60 °C for 3 hours. Measure the contact angle for one hour every 5 minutes to find the change in contact angle. Here we find that the contact angle of the sample changes with time. Note that the contact angle of the sample is 127.4° at 0 minutes and 120° after 115 minutes.

Conclusion

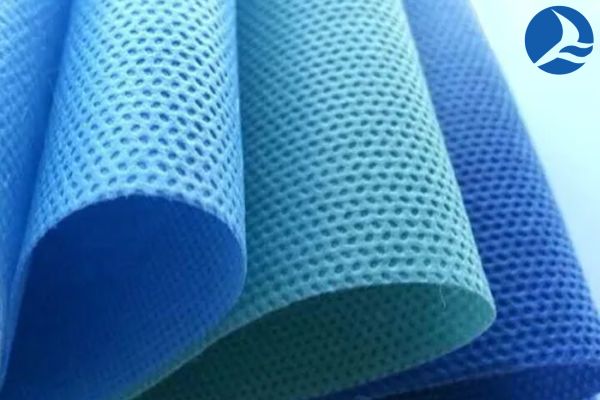

Nonwoven fabric is composed of webs, which are mutually reinforced by special, thermal or manual stretching of fibres or fibres (and foil perforation). They are bundled or laminated porous sheets made directly from single strands, liquid plastic or plastic. But, they are not made by weaving or sewing, and there is no need to exchange yarn for yarn. Non-woven fabric has a similar texture, composed of intermittent fibres and long strands, which are mechanically, thermally or soluble reinforced with each other. It contains 100% cotton or cotton as an ordinary hypoallergenic fibre that provides an ideal foundation for soil-based non-woven fabrics. However, hoping that you got sufficient information about hydrophobic non woven fabric and its properties.